- #SUPPORTED SCAFFOLD LADDER UPDATE#

- #SUPPORTED SCAFFOLD LADDER PLUS#

A competent person is defined as one who can identify existing and predictable hazards in the surroundings or working conditions that are unsanitary, hazardous, or dangerous to employees and has authorization to take prompt corrective measures to eliminate them. For all scaffolds not specifically mentioned, each employee must be protected by a PFAS or guardrail systems. Employees performing overhand bricklaying operations from a supported scaffold must be protected by a PFAS or guardrail system (with a minimum 200-pound top rail capacity) from all open sides and ends of the scaffold, except at the side next to the wall being laid. Walkways located within a scaffold require a guardrail system (with a minimum 200-pound top rail capacity) installed within nine and one-half-inches of and along at least one side of the walkway. When the platform is supported by ropes, both a PFAS and a guardrail system (with a minimum 200-pound top rail capacity) are necessary for protection. Self-contained adjustable scaffolds need a guardrail system (with a minimum 200-pound top rail capacity) when the platform is supported by the frame structure. Crawling boards (chicken ladders) require a PFAS, a guardrail system (with a minimum 200-pound top rail capacity), or a three-fourth inch diameter grabline or equivalent handhold securely fastened beside each crawling board. Single-point or two-point adjustable suspension scaffolds require both a PFAS and a guardrail system for protection. Boatswain's chairs, catenary scaffolds, float scaffolds, needle beam scaffolds, or ladder jack scaffolds require a personal fall arrest system (PFAS) to protect employees. 451(g)(1)(i) through (vii), scaffolding work has the following requirements for fall protection: Fall ProtectionĪs cited in OSHA’s E-tool. Non-compliance with OSHA scaffolding requirements can result in serious consequences, including penalties and fines. Inspections must be conducted by a competent person, and any defects or deficiencies must be addressed promptly. Regular inspections and maintenance of scaffolds are also required to ensure their continued safety and stability. Training must cover the hazards associated with scaffold use, as well as the proper use, inspection, and maintenance of scaffolds. OSHA also requires that workers who use scaffolds receive proper training and certification. It must also be able to support six times the maximum intended load. The platform must be fully planked and have a minimum width of 18 inches. Tiebacks must be installed to prevent the scaffold from swaying or tipping. #SUPPORTED SCAFFOLD LADDER PLUS#

Suspension ropes must be made of materials that are strong and durable enough to support their own weight, plus six times the maximum intended load. Specific requirements for suspended scaffolds include suspension ropes, tiebacks, and platform construction.

Bracing is required to provide additional stability to the scaffold. Guardrails must be installed on all open sides and ends of platforms that are more than 10 feet above the ground or floor level.

They must also be able to support four times the maximum intended load. Platforms must be fully planked and have a minimum width of 18 inches.

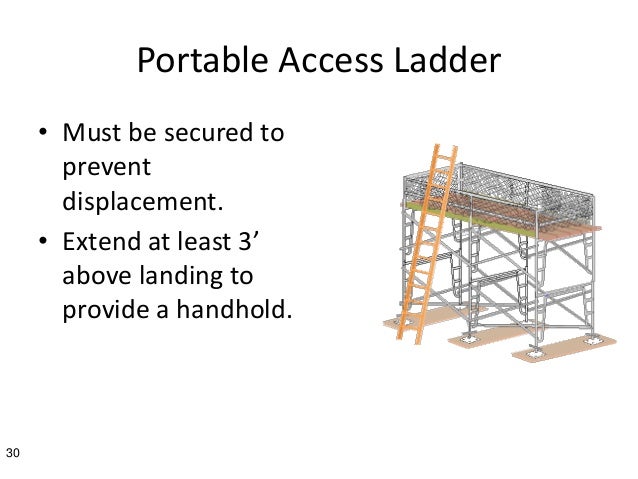

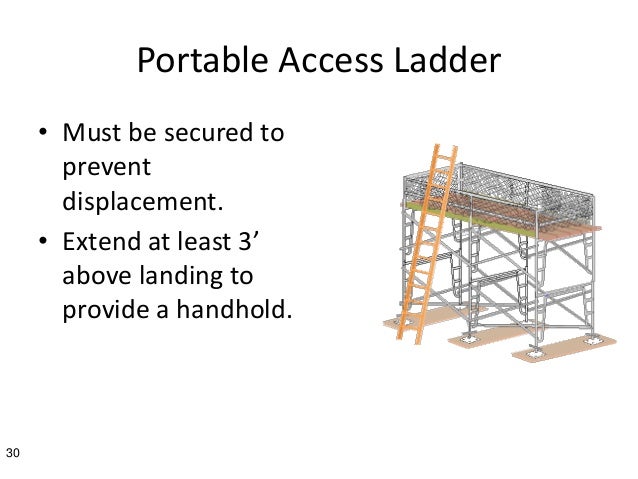

Specific requirements for supported scaffolds include platforms, guardrails, and bracing. Scaffolds must also have proper access, which may include stairways, ladders, or ramps. They must be stable and capable of supporting their own weight, plus four times the maximum intended load. Scaffolds must be designed by a qualified person and constructed in accordance with that design. OSHA Requirements for ScaffoldingĪs per the OSHA Scaffold General Requirements ( 1926 Subpart L), there are regulations for all scaffolds in terms of design and construction, stability, capacity, and access. In this article, we will provide an overview of OSHA scaffolding requirements, including the general requirements for all scaffolds, specific requirements for supported and suspended scaffolds, fall protection, safe distances from energized power lines, and training and certification requirements. #SUPPORTED SCAFFOLD LADDER UPDATE#

The most recent update was made in 2016, when OSHA published a final rule on walking-working surfaces and personal protective equipment (PPE) that included significant changes to the scaffolding requirements.

Since then, OSHA has updated and revised its scaffolding requirements several times to keep pace with changes in the industry and new technologies. These regulations were designed to improve the safety of scaffolding operations and reduce the risk of worker injuries and fatalities. In fact, OSHA's first set of scaffolding regulations was issued in 1971, shortly after the agency was established. OSHA scaffolding requirements have been in place since the agency's inception.

0 kommentar(er)

0 kommentar(er)